Normally there are two ways to make steel products’ with mirror surface.One way is Chemical reagent steeping,and the other one is via stainless steel automatic polishing machine which is more environmentally friendly than chemical way.

Chemical reagent way polishing is a method of eliminating the wear scar and eroding the flatness by the chemical agent's selective dissolution of the stainless steel surface.The biggest disadvantage is polluting environment,so more and more workshops choose automatic polishing machine to make steel surface grinding buffing.

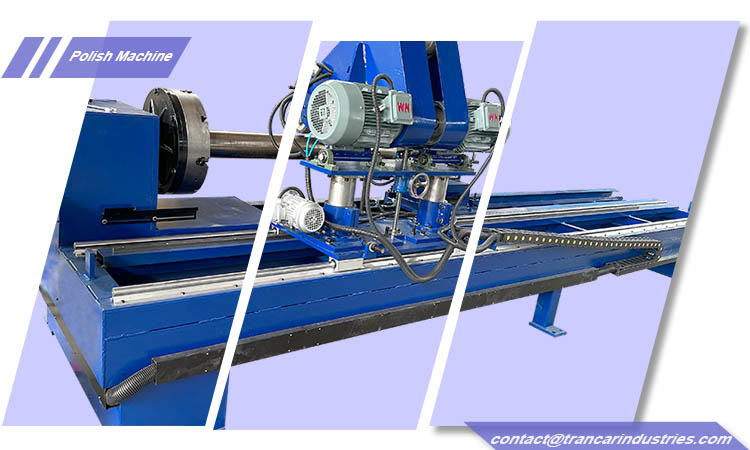

The principle of stainless steel polishing machine:the grinding wheel is rotated by the motor,and friction is generated with the rotating workpiece on the grinding rotary table, and the cutting force is generated by friction to smooth the uneven surface of the workpiece to achieve the purpose of polishing.

Both abrasive sanding belts and buffing wheels are available on automatic polishing machine,grit mash from 80# to 1200#,and it will be easy to get mirror finishing via polishing machine step by step.

You could get surface roughness Ra≦0.25μm after buffing via polishing machine,via it’s hard to reach it via chemical way.Stainless steel mirror polishing generally uses a polishing machine to polish,the polishing machine can remove scratches,spots,sag on stainless steel workpiece surface,so that the surface of the workpiece is bright,smooth and mirror-like.

Should any requirements on steel metal surface treatment,welcome contact us directly.There is at least one auto grinding solution will meet your demands.